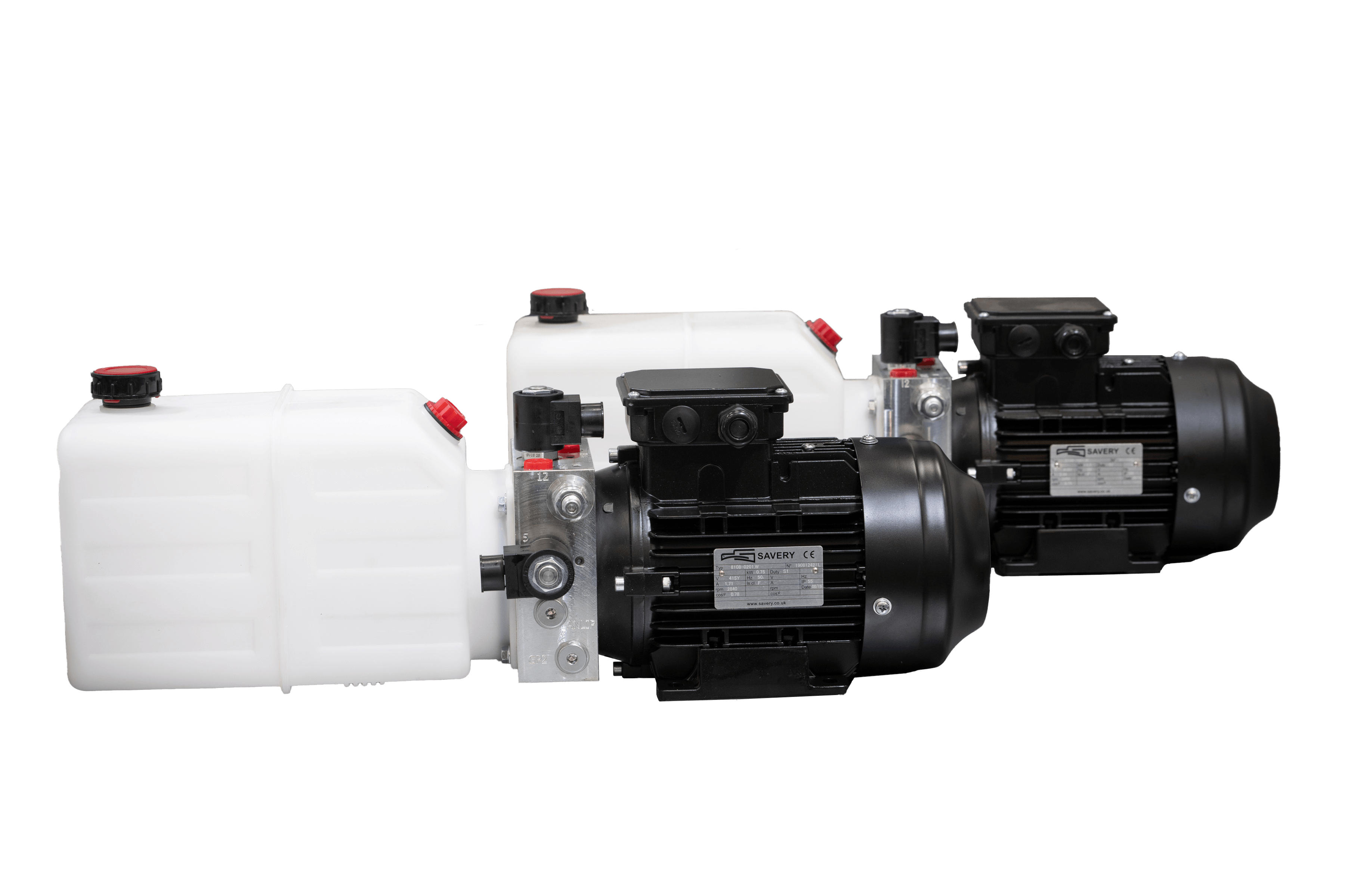

With over 300 years of engineering experience, Savery designs and manufactures high-quality hydraulic systems tailored to your needs. If you're interested in this product, fill in our contact form, and our team will be in touch.

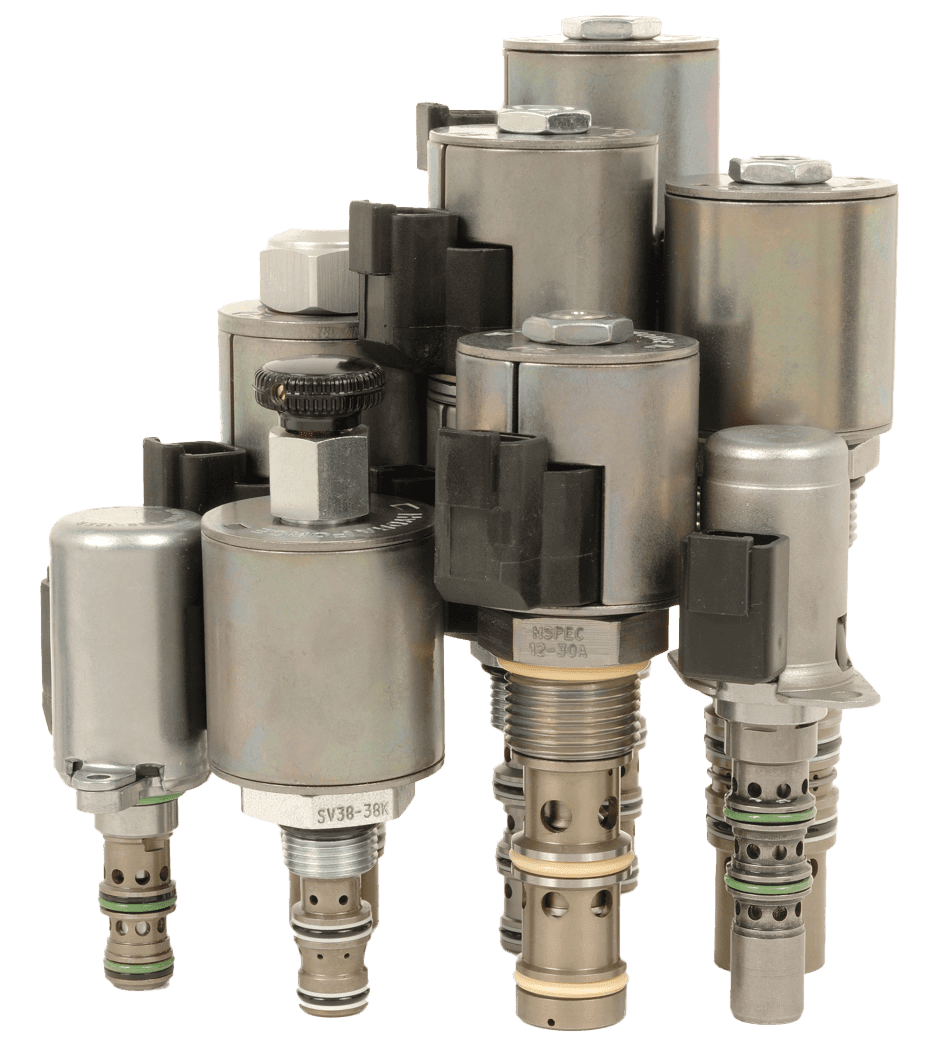

Contact usTS10-27 Proportional Pressure Relief Valve with (TS10-27)

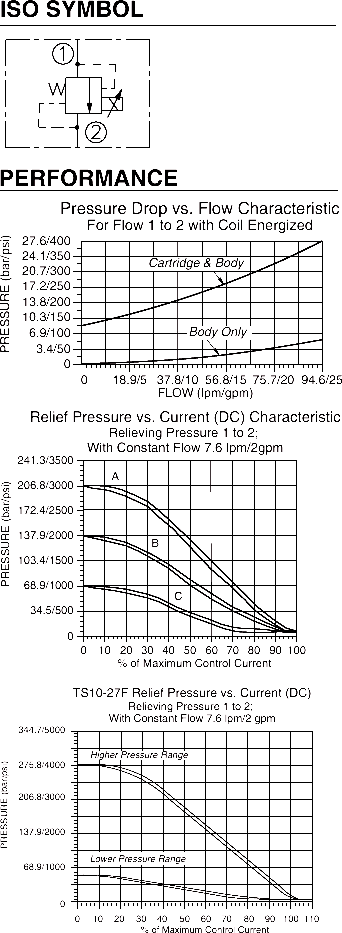

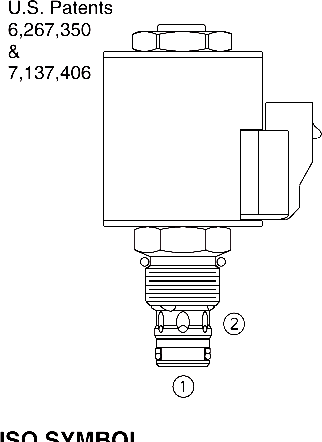

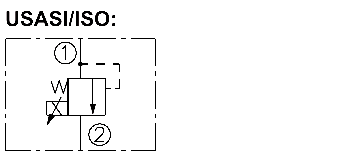

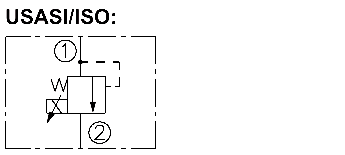

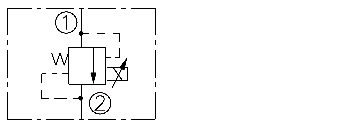

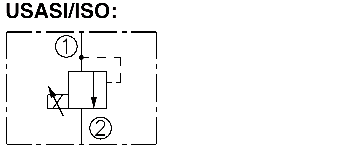

A screw-in, cartridge-style, pilot-operated, spool-type hydraulic relief valve, which can be infinitely adjusted across a prescribed range using a variable electric input. Pressure output is inversely proportional to DC current input. This valve is intended for use as a pressure-limiting device in demanding applications.

Product Operation

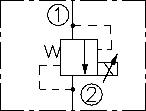

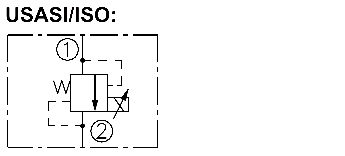

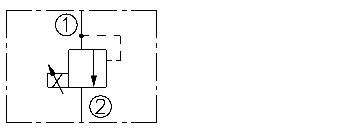

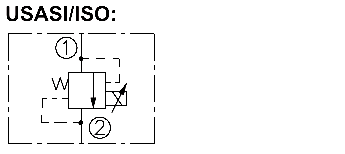

The TS10-27 blocks flow from 1 to 2 until sufficient pressure is present at 1 to open the valve by overcoming the preset induced spring force. With no current applied, the valve will relieve at ±50 psi of the range maximum. Applying current to the coil decreases the induced spring force, thereby reducing the valve setting.

Note: This valve is ideal for hydraulic fan drive applications. Consult factory for electronic controllers specifically designed for fan drive applications.

Product Features

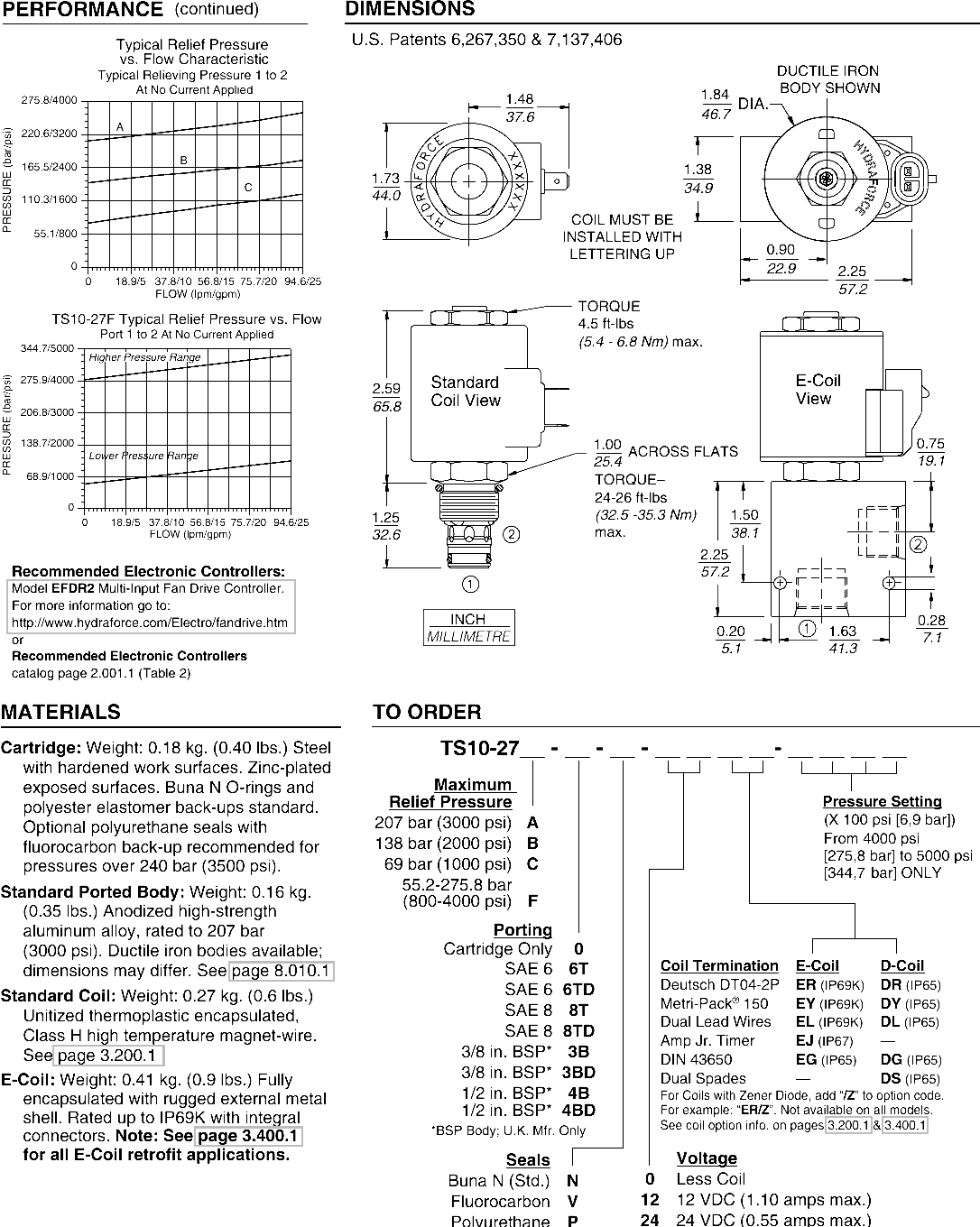

• 12 and 24 volt coils standard.

• Industry common cavity.

• Adjustable or fixed relief pressure settings.

• Higher pressure 330.9 bar (4800 psi) factory-set model F available.

Product Ratings

Pressure Rating: 275.8 bar (4000 psi) at Port 1;TS10-27F 330.0 bar (4800 psi)

Proof Pressure: 344.7 bar (5000 psi) at Port 1; 206.8 bar (3000 psi) at Port 2; TS10-27F 413.7 bar (6000 psi) at Port 1 and 206.8 bar (3000 psi) at Port 2

Burst Pressure: 814 bar (11,800 psi) at all ports

Electrical Parameters:

Coil

*Typical Max. Current

(A) at 0 gpm

Typical Resistance

± 5% @ 20°C (ohms)

Typical Apparent

Inductance (mH)

12 VDC

24 VDC

12 VDC

24 VDC

12 VDC

24 VDC

D-Coil1.100.556.7 ±5%25 ±5%134 mH500 mH

E-Coil1.200.557.32 ±5%29.3 ±5%139 mH560 mH

Relief Pressure Range from Zero to Maximum Control Current:

A: 206.8–6.9 bar (3000–100 psi)

B: 138–6.9 bar (2000–100 psi)

C: 69–6.9 bar (1000–100 psi)

F: Factory Set: 275.8–55.2 bar (4000–800 psi) *Consult factory for detailed current range for particular pressure setting. Note: Tank port pressure is additive to valve setting.

Rated Flow: 75.7 lpm (20 gpm), P = 20.7 to 24.1 bar (300 to 350 psi), cartridge only, 1 to 2 coil energized

Hysteresis (PMW 200 Hz):

A: 3.2%;

B: 3.0%;

C: 4.8%

F: 4%

Pressure Rise:

A: 0.48 bar/lpm (26.5 psi/gpm);

B: 0.36 bar/lpm (20 psi/gpm);

C: 0.46 bar/lpm (25 psi/gpm)

F: 1.86 bar/lpm (27 psi/gpm)

Operating Fluid Temperature: -40 to 100°C (-40 to 212°F) with standard Buna N seals; -26 to 204°C (-15 to 400°F) with fluorocarbon seals; -54 to 107°C (-65 to 225°F) with polyurethane seals.

Filtration: See page 9.010.1

Fluids: Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 sus); See Temperature and Oil Viscosity, page 9.060.1

Installation Recommendation: When possible, the valve should be mounted below the reservoir oil level. This will maintain oil in the armature preventing trapped air instability. If this is not feasible, mount the valve horizontally for best results.

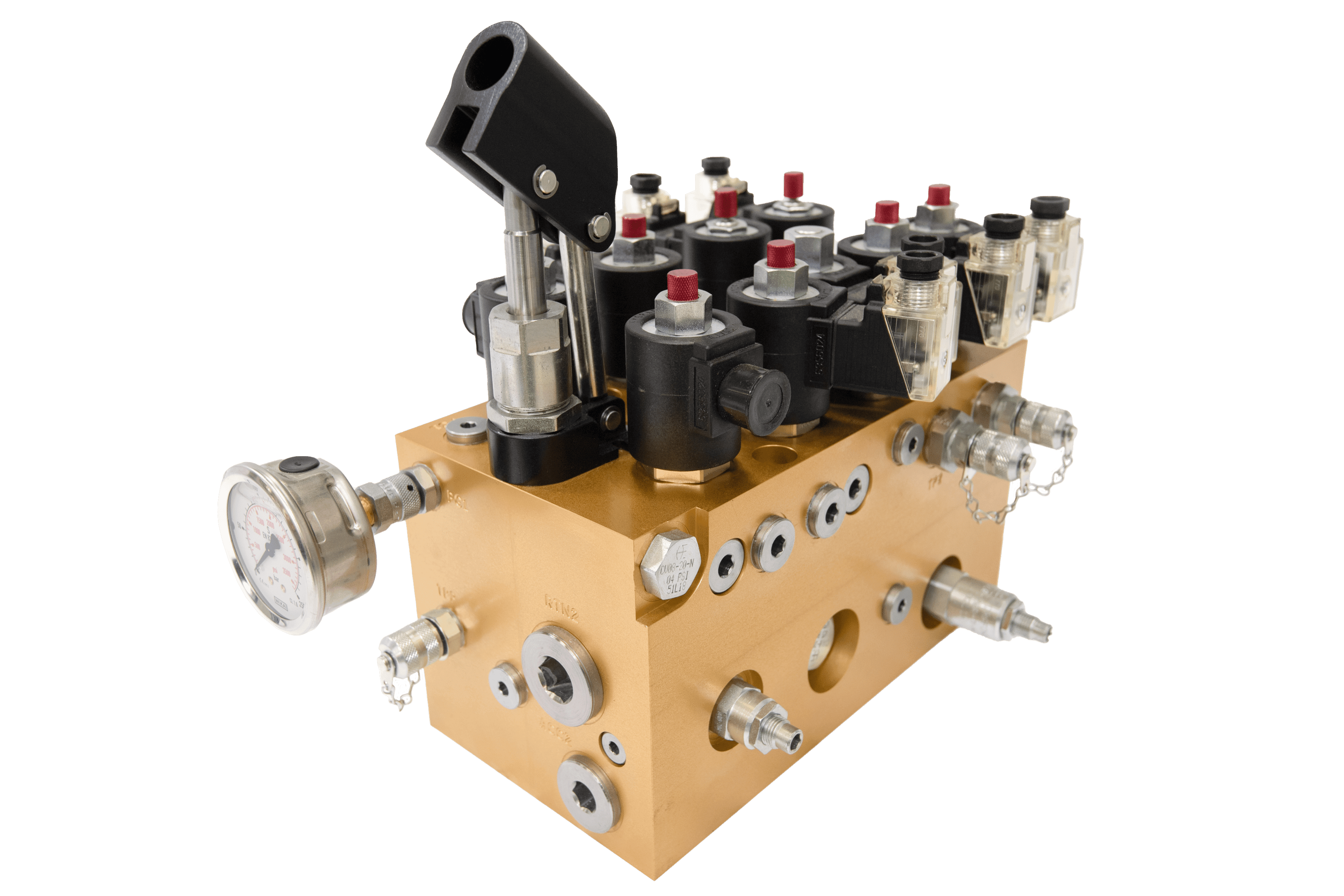

Cavity: VC10-2; See page 9.110.1

Cavity Tool: CT10-2XX; See page 8.600.1

Seal Kit: SK10-2X-B; See page 8.650.1

Coil Nut: Part No. 4540550; For E-coils manufactured prior to 1-1-04, see page 3.400.1“>3.400.1“>3.400.1 for coil nut info.U.S. Patents6,267,350&7,137,406