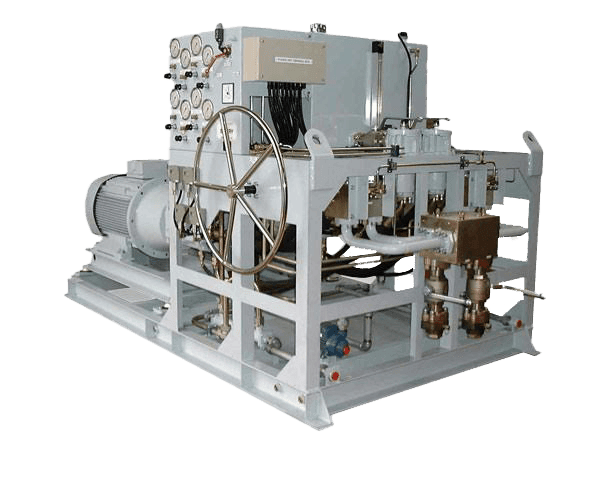

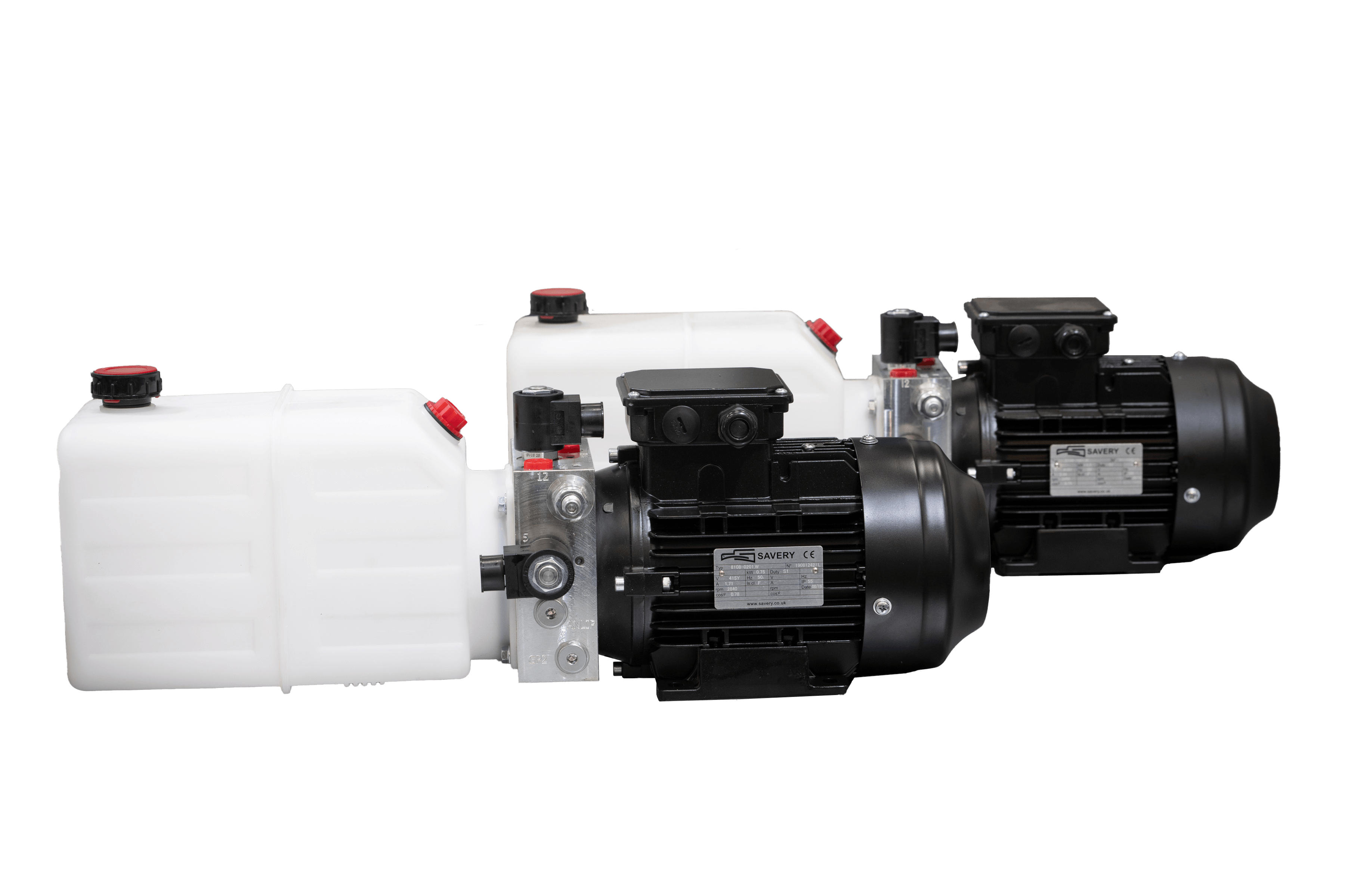

With over 300 years of engineering experience, Savery designs and manufactures high-quality hydraulic systems tailored to your needs. If you're interested in this product, fill in our contact form, and our team will be in touch.

Contact usTS10-36 Proportional Electric Reducing/Relieving (TS10-36)

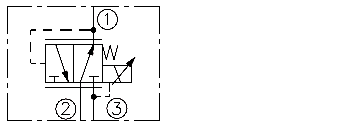

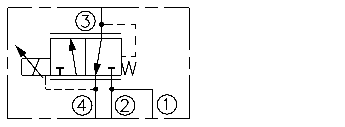

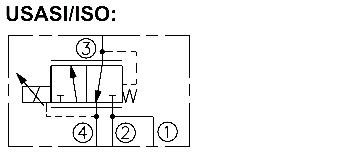

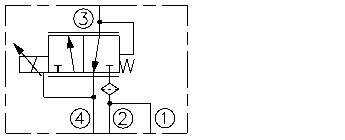

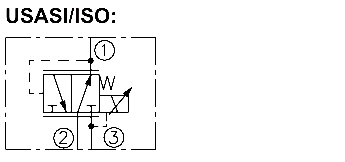

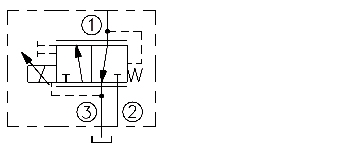

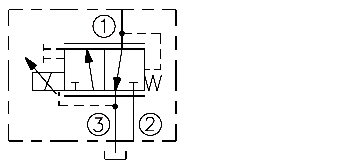

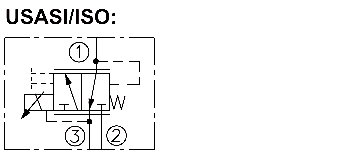

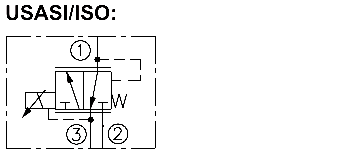

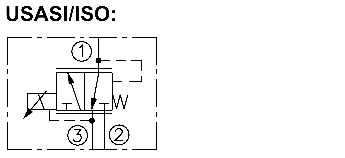

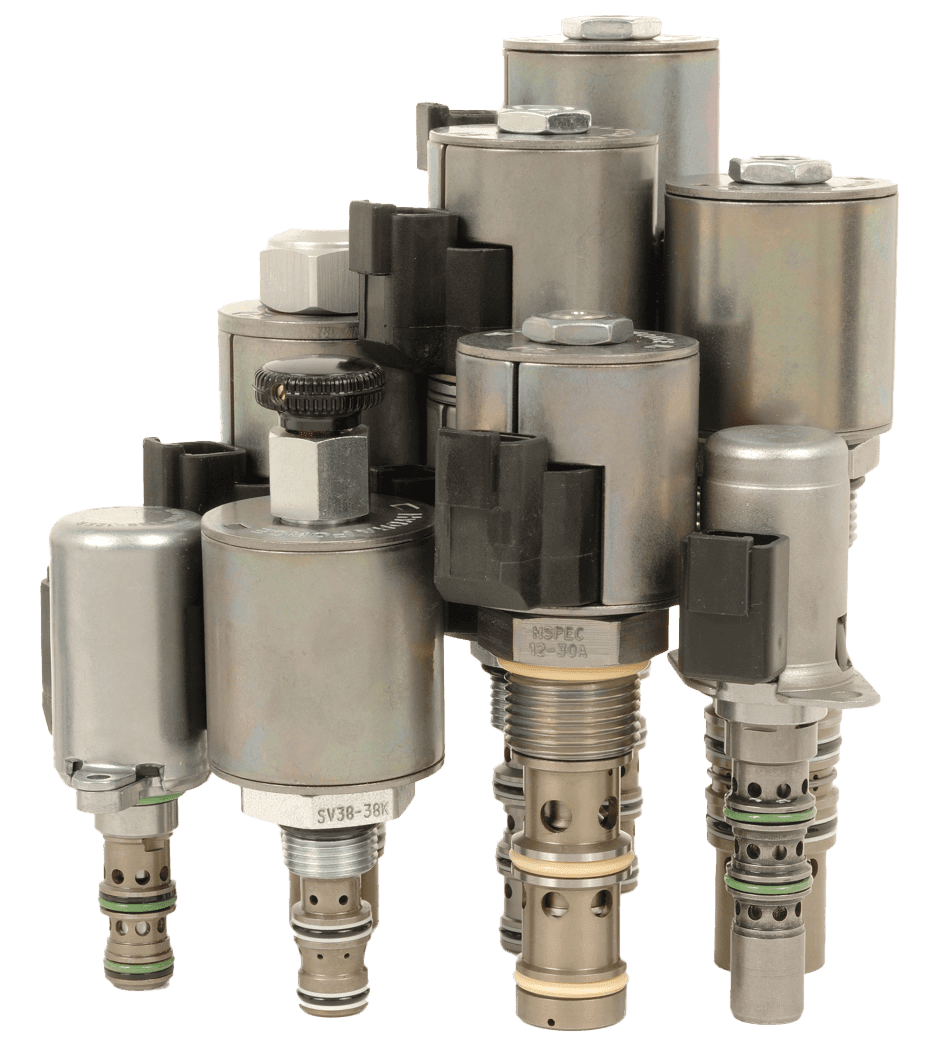

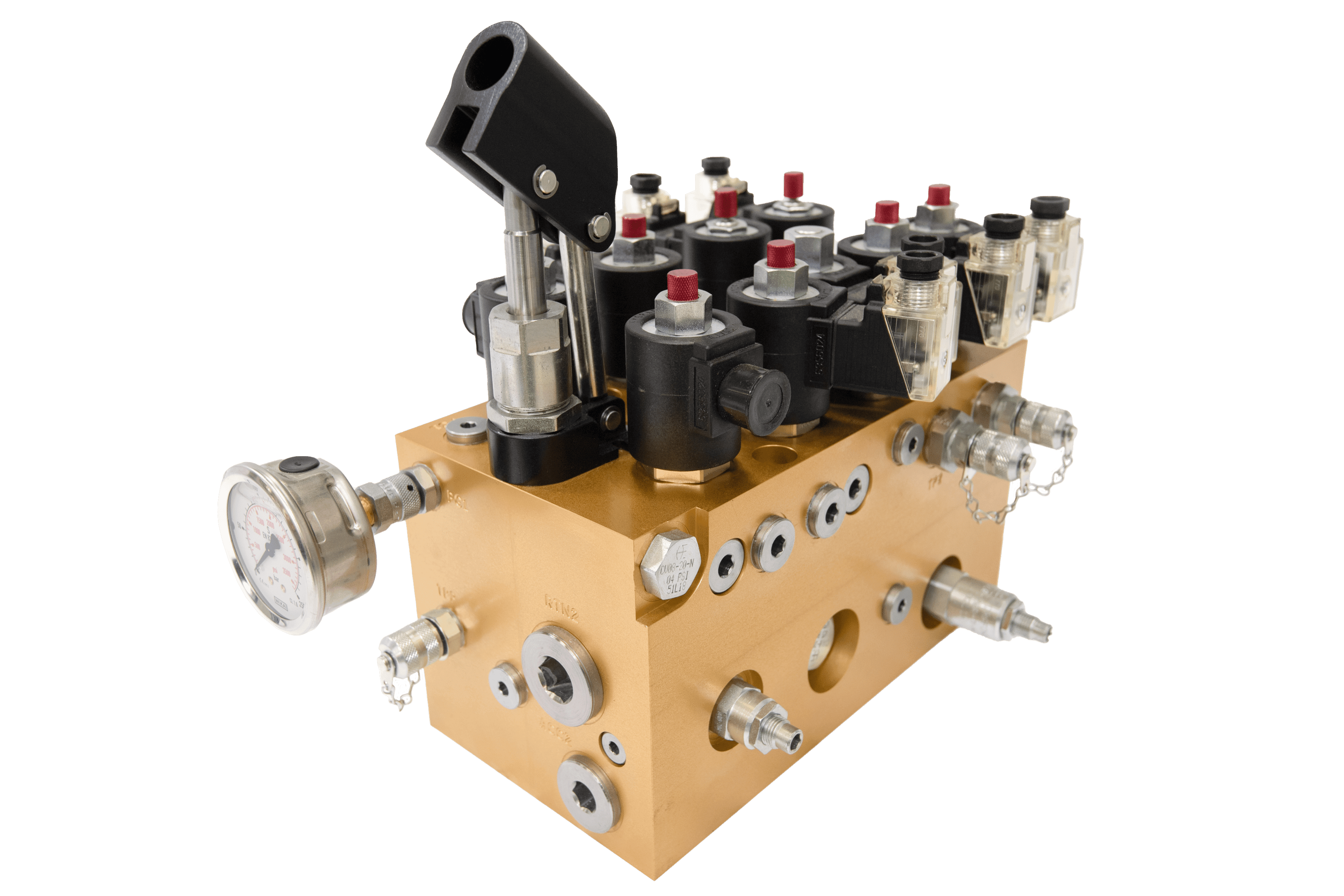

A screw-in, cartridge-style, pilot-operated, spool-type reducing/relieving valve, which can be infinitely adjusted across a prescribed range using a variable electric input. Pressure output is proportional to DC current input. This valve is intended for use as a pressure limiting device in demanding applications.

Product Operation

With current applied to the valve coil, the TS10-36 blocks flow from 2 to 1 until sufficient pressure is present at 1 to open the pilot section by offsetting the electrically induced solenoid force. Increasing electric current will increase the control (reduced) pressure at 1. With no current applied to the solenoid, the valve will relieve pressure at 1 at approximately 6,9 bar (100 psi), regardless of pressure at 2.

The TS10-36 has an optional manual override feature. This allows the valve to be set when the electric supply is lost. The manual setting is added to the electric setting, so when using the manual override feature to establish a minimum setting, care is required to prevent the system from becoming over-pressurized.

Product Features

• Manual override option.

• Industry common cavity.

• 12 and 24 volt coils standard.

• Optional waterproof E-Coils rated up to IP69K.

Product Ratings

Maximum Operating Pressure: 241 bar (3500 psi)

Electrical Parameters:

Coil

Typical Max. Current

(A) at 0 gpm

Typical Resistance ±

5% @ 20°C (ohms)

Typical Apparent

Inductance (mH)

12 VDC

24 VDC

12 VDC

24 VDC

12 VDC

24 VDC

D-Coil1.100.557.25 ±5% 28.35 ±5% 141626

E-Coil1.200.607.3 ±5%29.4 ±5%139600

Relief Pressure Range from Zero to Maximum Control Current:

A: 6.9–207 bar (100–3000 psi)

B: 6.9–159 bar (100–2300 psi)

C: 6.9–117 bar (100–1700 psi)

Rated Flow: 57 lpm (15 gpm), P=22.8 bar (330 psi), Cartridge only,1 to 3 coil de-energized

Maximum Pilot Flow: 0.21 lpm (0.08 gpm)

Flow Path: Free Flow: 1 to 3 coil de-energized; Reduced: 2 to 1 coil energized; Relieving: 1 to 3 coil energized

Temperature: -40 to 100°C (-40 to 212°F) for Buna N seals-26° to 204°C (-15° to 400°F) with Fluorocarbon V seals

Filtration: See page 9.010.1

Fluids: Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 sus); See Temperature and Oil Viscosity, page 9.060.1

Installation Recommendation: When possible, the valve should be mounted below the reservoir oil level. This will maintain oil in the armature preventing trapped air instability. If this is not feasible, mount the valve horizontally for best results.

Cavity: VC10-3; See page 9.110.1

Cavity Tool: CT10-3XX; See page 8.600.1

Seal Kit: SK10-3X-BM; See page 8.650.1 (X = seal option)

Coil Nut: Part No. 4540560; For E-coils made prior to 1-1-04, see page 3.400.1U.S. Patent 7,137,406

2.900.1Relief Pressurevs. Current (DC) Characteristic200 Hz PWMReducing Pressure 2 to 1PRESSURE (bar/psi)507251001450150217520029002503625% of Maximum Control Current201030507090406080100ABCELECTRO-PROPORTIONAL VALVES – PRESSURE CONTROL

HYDRAFORCE.com®