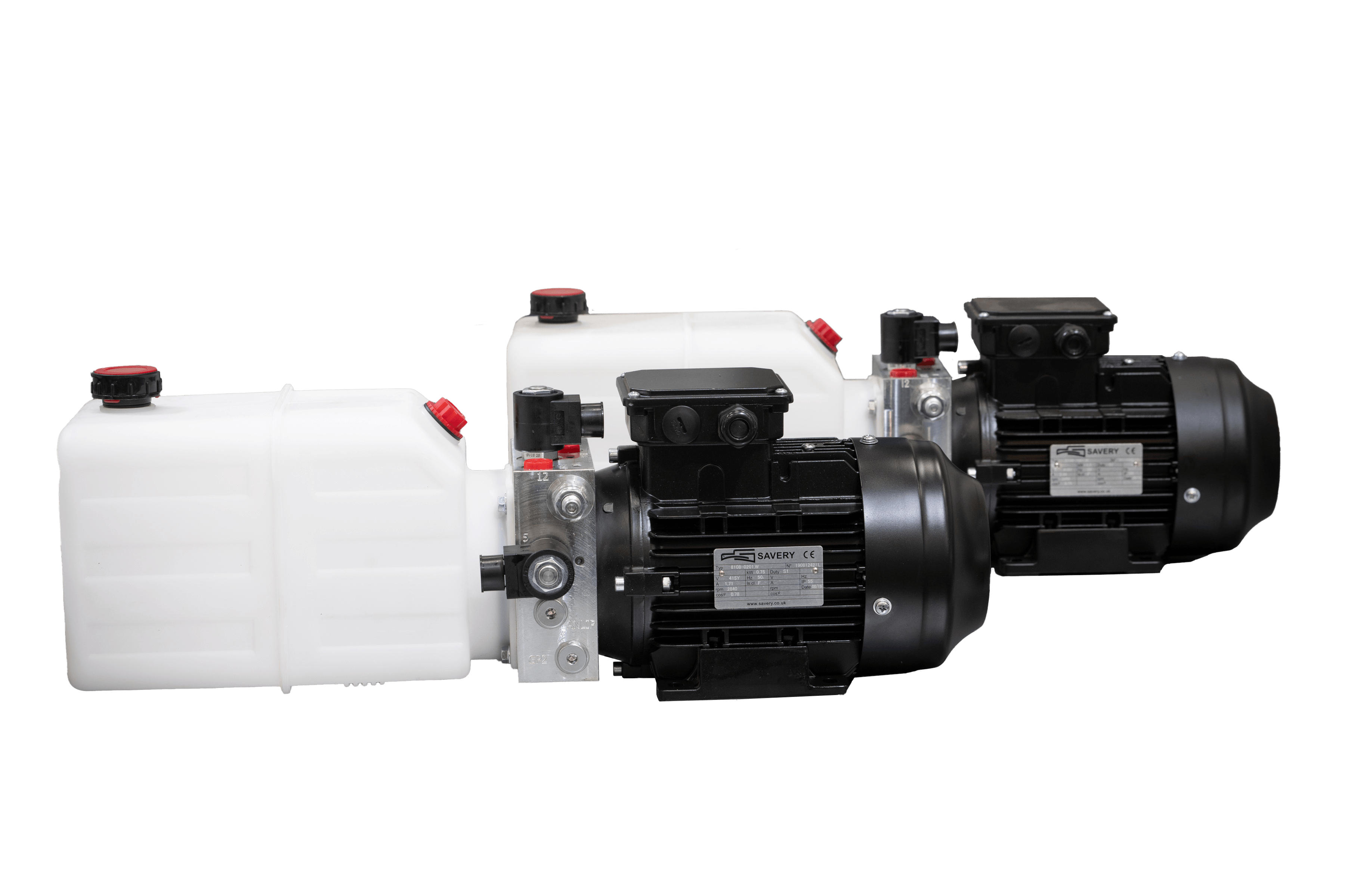

With over 300 years of engineering experience, Savery designs and manufactures high-quality hydraulic systems tailored to your needs. If you're interested in this product, fill in our contact form, and our team will be in touch.

Contact usZL72-31 Proportional, Bi-Directional Flow Control, (ZL72-31)

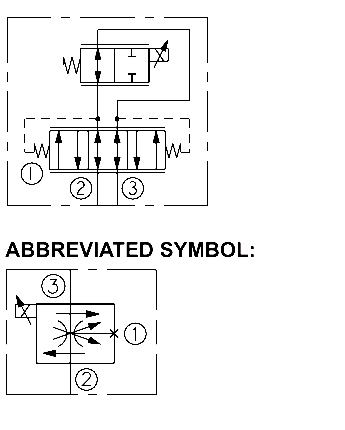

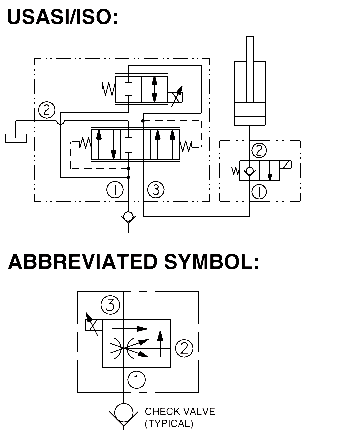

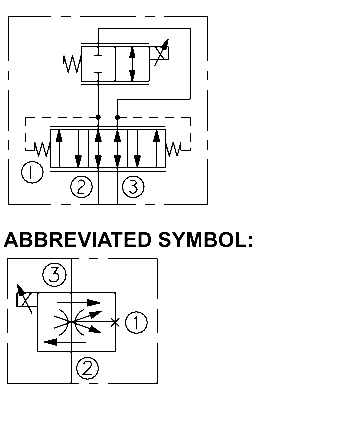

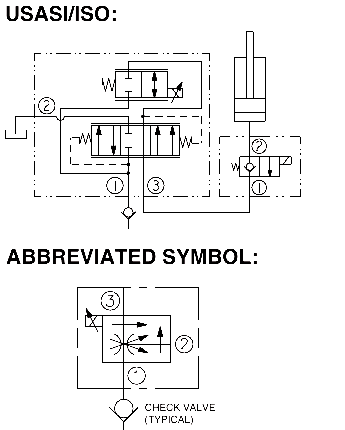

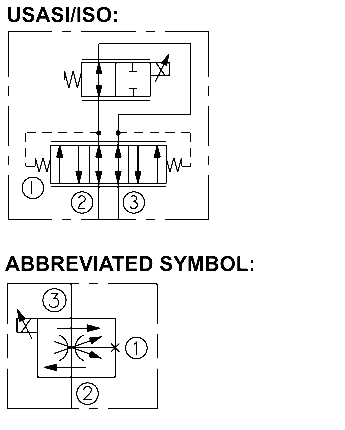

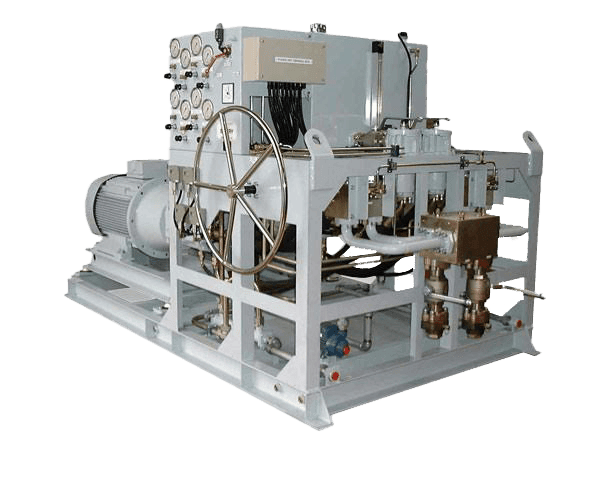

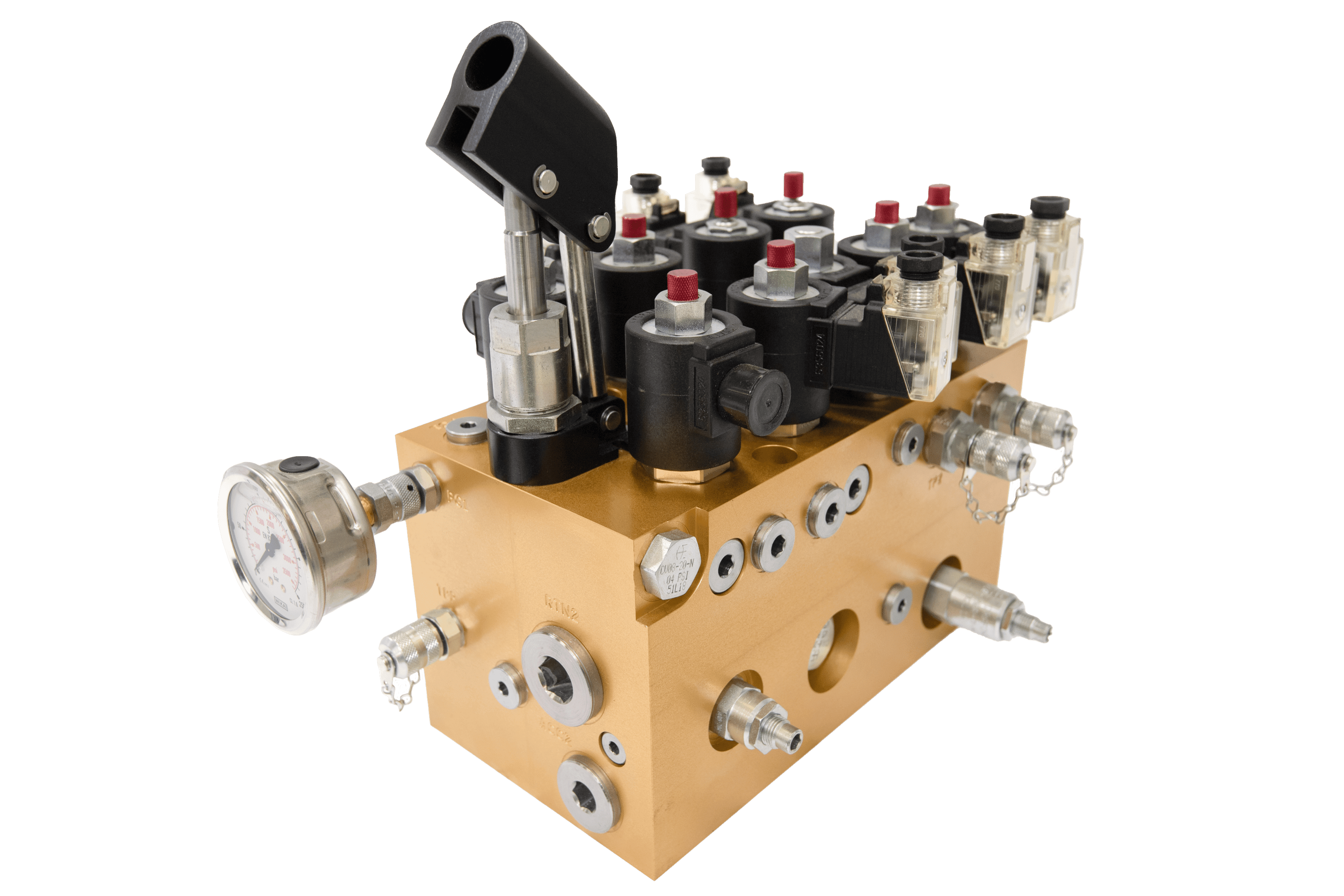

A solenoid-operated, electrically-variable, pressure-compensated, spool-type, normally open when de-energized, proportional, bi-directional flow control valve. An internal compensator spool provides compensated flow across the proportional orifice regardless of flow direction.

Product Operation

The ZL72-31 provides regulated flow in both directions: from port ➁ to port ➂, or from port ➂ to port ➁. Port ➀ should be blocked. Regulated flow is inversely proportional to electric current applied to the solenoid.

Operation of Manual Override: To Engage: Turn clockwise approximately 1 turn to reach start point. Continue

another approximately 5 turns to full shift.To Disengage: Turn counterclockwise approximately 6 turns until positive stop

is found.

Product Features

• Excellent linearity and hysteresis.

• Hardened spool and cage for long life.

• Effi cient wet armature construction.

• Optional coil voltages and terminations.

• Cartridges voltage interchangeable.

Product Ratings

Maximum Operating Pressure: 240 bar (3500 psi)

Regulated Flow: 0-50 lpm (0-13 gpm)

Internal Leakage: 0.38 lpm (0.10 gpm) maximum at 1.5 amp

Electrical: 2 standard voltage ratings

Temperature: -40 to 120°C with Buna N seals

Filtration: See page 9.010.1

Fluids: Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 sus); See Temperature and Oil Viscosity, page 9.060.1

Installation: No restrictions; See page 9.020.1.

Cavity: VC12-3; See page 9.112.1

Cavity Tool: CT12-3X-XX; See page 8.600.1

Seal Kit: SK12-3X-MM; See page 8.650.1

Threshold Current 150 ± 50 mA 75 ± 25 mA

Coil Voltage12 VDC24 VDC

Max. Control Current 1250 ± 100 mA 625 ± 50 mAU.S. Patent6,167,906

ELECTRO-PROPORTIONAL VALVES—FLOW CONTROLS

HYDRAFORCE.com®

• Unitized, molded coil design.

• Coil waterproofi ng standard.

• Manual override option.

Recommended Electronic Controllers:See page 2.001.1 or our Electronics catalog.