With over 300 years of engineering experience, Savery designs and manufactures high-quality hydraulic systems tailored to your needs. If you're interested in this product, fill in our contact form, and our team will be in touch.

Contact usZL70-36 Proportional, Bi-Directional Flow Control, (ZL70-36)

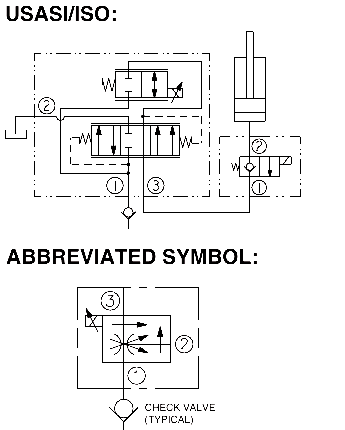

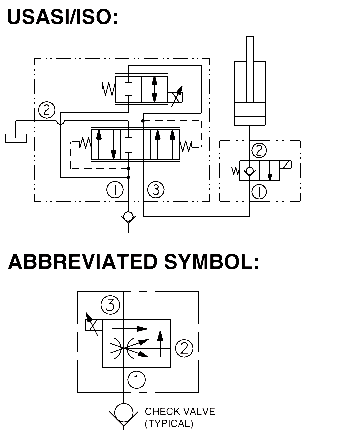

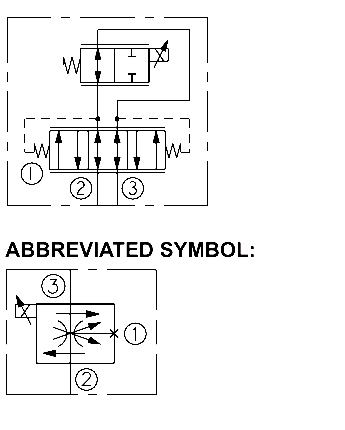

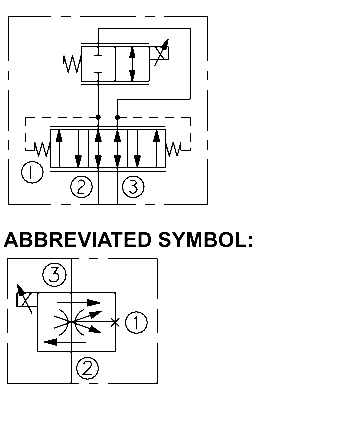

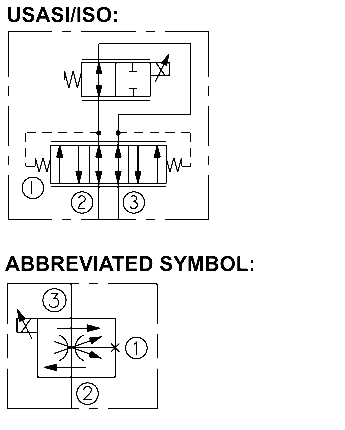

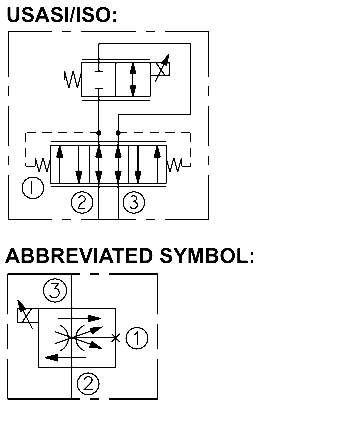

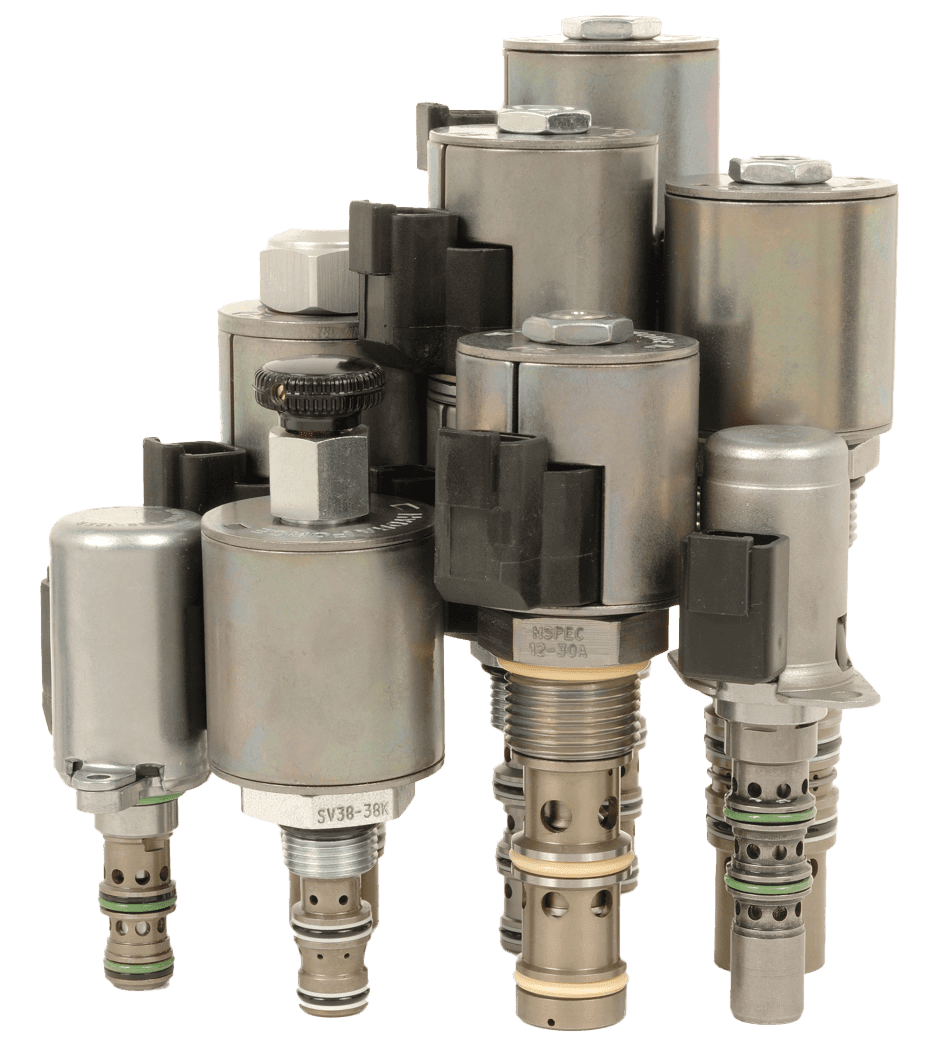

A solenoid-operated, electrically-variable, three-port, pressure-compensated, spool-type, normally closed when de-energized, proportional, bi-directional, priority-type flow control valve.

Product Operation

The ZL70-36 provides priority regulated flow from port 1 to port 3 with bypass at port 2; or regulated flow from port 3 to port 2 with port 1 blocked externally, typically with a check valve (see symbol drawing). Regulated flow is proportional to electric current applied to the solenoid.

Application Notes: The ZL70-36 may be used for single-acting cylinder applications where lowering is provided by gravity force. The ZL 70-36 has no minimum load restrictions provided the load is enough to overcome cylinder friction and other frictions in the system. At low loads, the lowering speed can be slower than at heavier load if pressure drop is less than the compensation value of the valve.

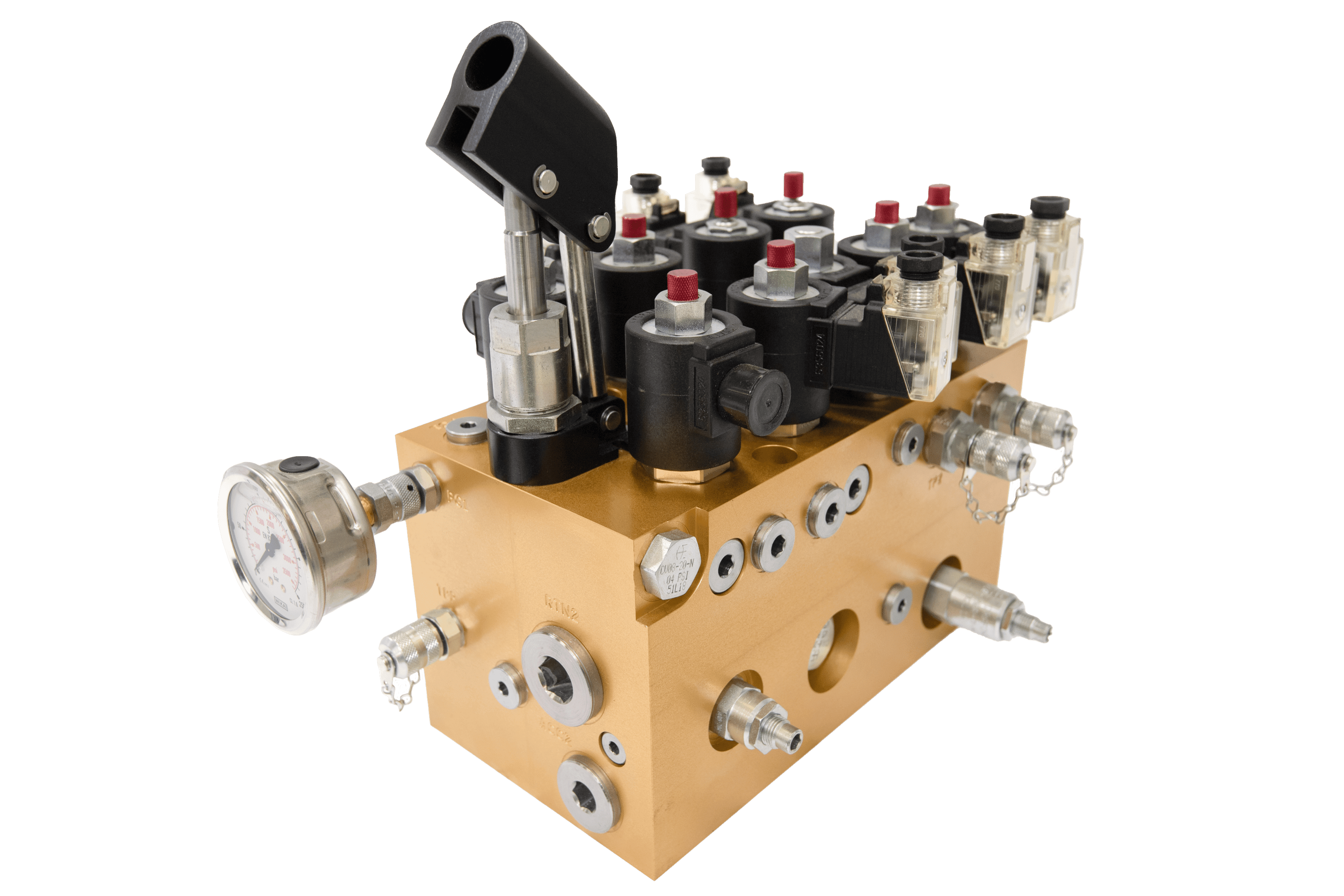

The hydraulic circuit must include a check valve and a poppet-type solenoid valve (SV08-20 type) connected as shown on the circuit symbol and placed close to the ZL70-36 valve, if possible in the same manifold. See Application Guide.

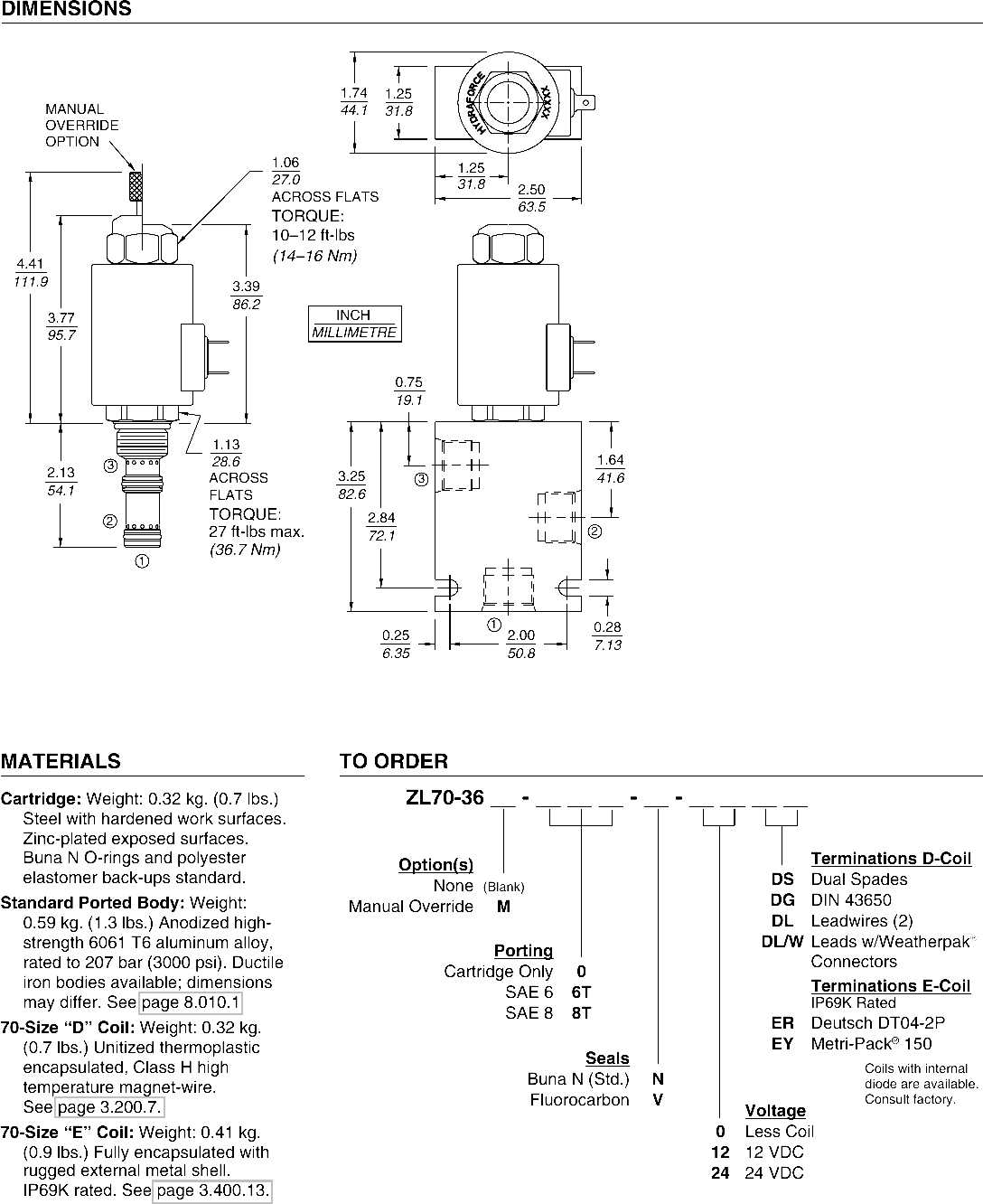

Operation of Manual Override: To Engage: Turn clockwise approximately 1 turn to reach start point. Continue another approximately 5 turns to full shift. To Disengage: Turn counterclockwise approximately 6 turns until positive stop is found.

Product Features

• Excellent linearity and hysteresis.

• Efficient wet armature construction.

• Hardened spool and cage for long life.

• Manual Override option.

• Optional coil voltages and terminations.

Product Ratings

Maximum Operating Pressure: 240 bar (3500 psi)

Regulated Flow: 0–19 lpm (0–5.0 gpm);

Input Flow: 0–25.5 lpm (0–6.5 gpm)

Internal Leakage: 0.38 lpm (0.10 gpm) maximum at zero current

Electrical: 2 standard voltage ratings

Temperature: -40 to 120°C with Buna N seals

Filtration: See page 9.010.1

Fluids: Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 sus); See Temperature and Oil Viscosity, page 9.060.1

Installation: No restrictions; See page 9.020.1.

Cavity: VC10-L3; See page 9.110.1;

Cavity Tool: CT10-3X-XX; See page 8.600.1

Seal Kit: SK10-3X-MM; See page 8.650.1

Threshold Current 300 ± 100 mA 150 ± 50 mA

Coil Voltage12 VDC24 VDC

Max. Control Current 1400 ± 100 mA 700 ± 50 mA