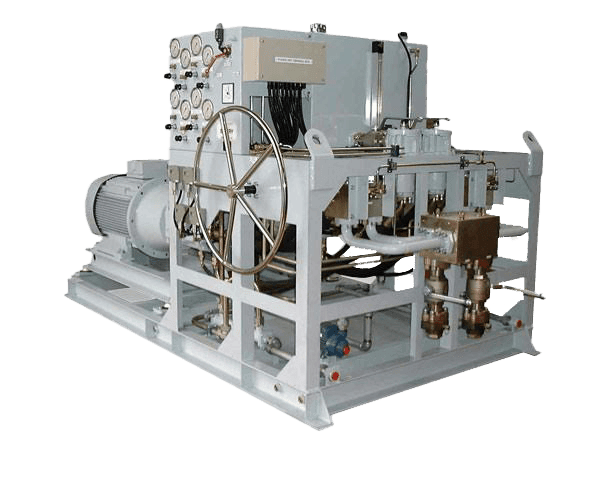

With over 300 years of engineering experience, Savery designs and manufactures high-quality hydraulic systems tailored to your needs. If you're interested in this product, fill in our contact form, and our team will be in touch.

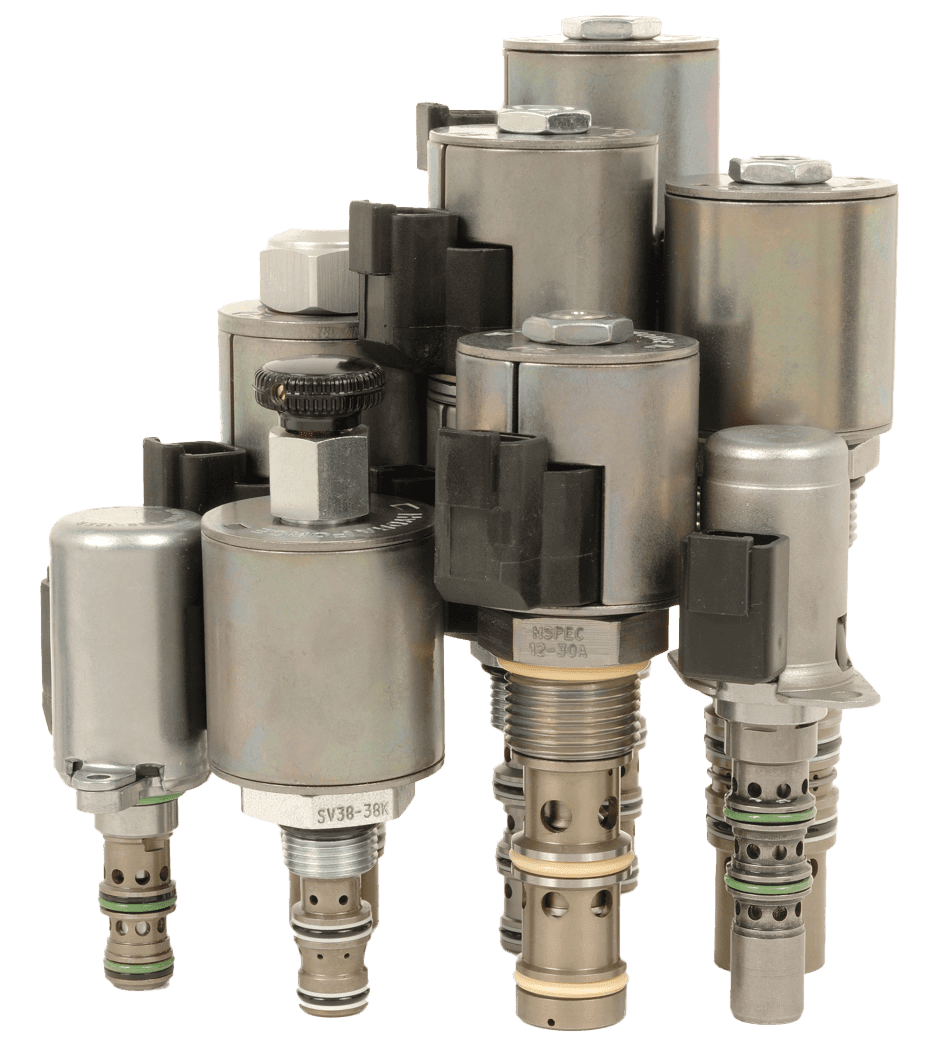

Contact usMR10-20 Manual Rotary Flow Control (MR10-20)

A manually-adjustable variable orifice, offering linear control with adaptability to a variety of adjustment operators (ordered separately).

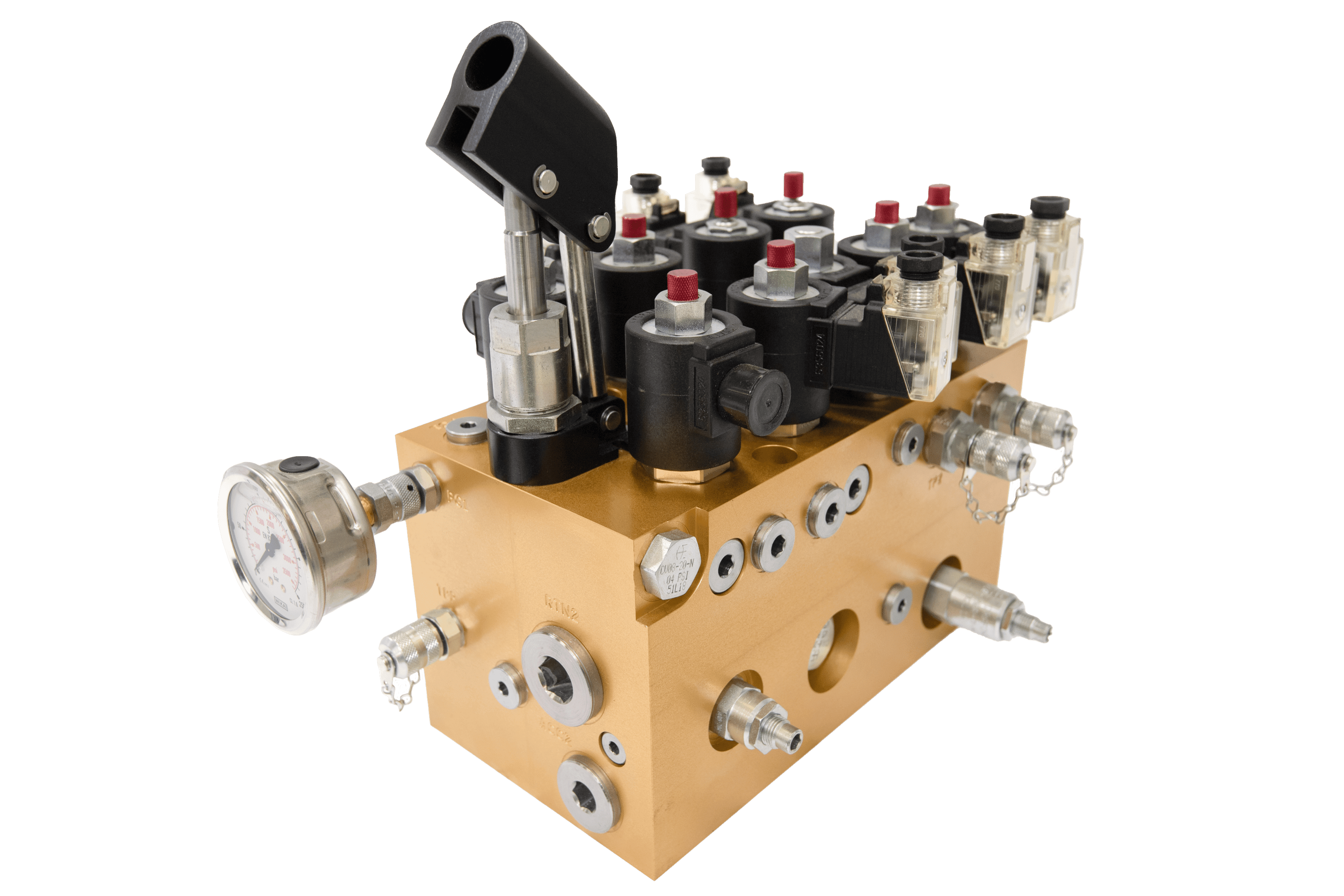

Product Operation

In extreme clockwise position, valve is fully closed (normally closed). Counterclock-

wise rotation of 180° gradually increases flow. The fi rst 10° (approx.) of rotation is

deadband. The last 15° of rotation increases flow very little. For a normally-open

version with counterclockwise rotation gradually decreasing flow, consult factory.

NOTE: Use of the valve in the ➀ to ➁ direction is not recommended if the plastic knob operator is used. Because of the low effort (internal bearing used) adjustment,

flow forces may cause setting change. The valve will operate ➀ to ➁ well with handle-type operator kits.

Product Features

• Ten-position detent or infi nite friction lock options.

• Good linearity in three flow range options.

• Adaptable to a variety of operators.

• Optional lock-down bracket.

• Heavy-duty construction.

• Low effort adjustment.

• Industry common cavity.

Product Ratings

Operating Pressure: 240 bar (3500 psi)

Max. Flow: See Performance Chart

Flow Rate Delivered at 5.5 bar (80 psi) Differential:

Model Code

Flow A 49 lpm (13 gpm) B 34 lpm (9 gpm) C 22 lpm (6 gpm)

Leakage in “Off” Position at 207 bar (3000 psi): 164 cc/min. (10 cu. in.)

Temperature: -40 to 120°C with standard Buna N seals

Torque Required to Change Position Under Load:@7 bar (100

psi): 3.9 Nm (35 lb.-in.)@ 240 bar (3500 psi): 5.1 Nm (45 lb.-in.)

Filtration: See page 9.010.1

Fluids: Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 sus); See Temperature and Oil Viscosity, page 9.060.1

Installation: No position restrictions; See page 9.020.1See page 4.780.2 for operator handles/knobs installation;See page 4.780.1 for lock-down bracket installation.

Cavity: VC10-2; See page 9.110.1

Cavity Tool: CT10-2XX; See page 8.600.1

Seal Kit: SK10-2X-M; See page 8.650.1

Lock-Down Bracket Kit: Part Number 5399000