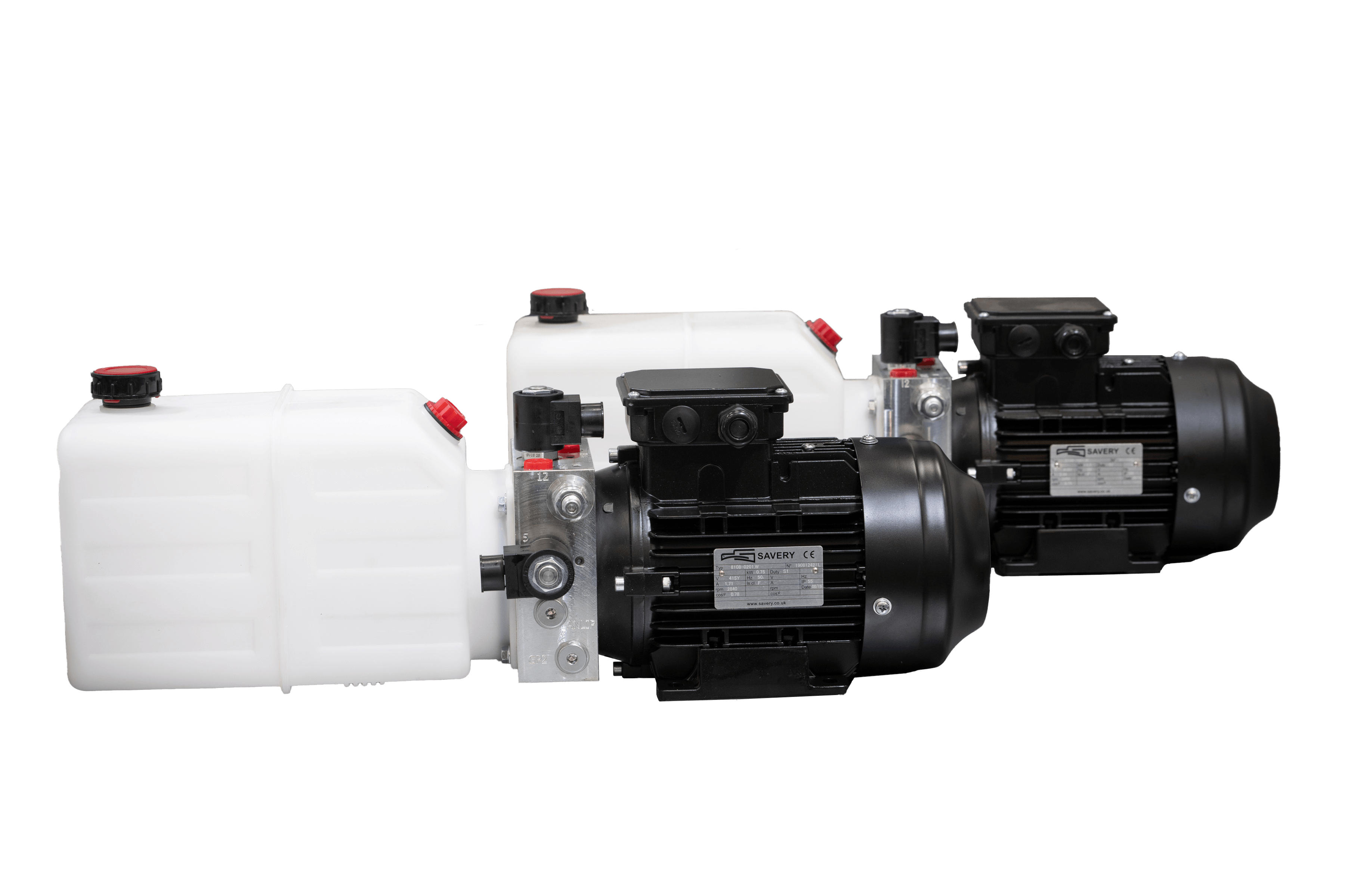

With over 300 years of engineering experience, Savery designs and manufactures high-quality hydraulic systems tailored to your needs. If you're interested in this product, fill in our contact form, and our team will be in touch.

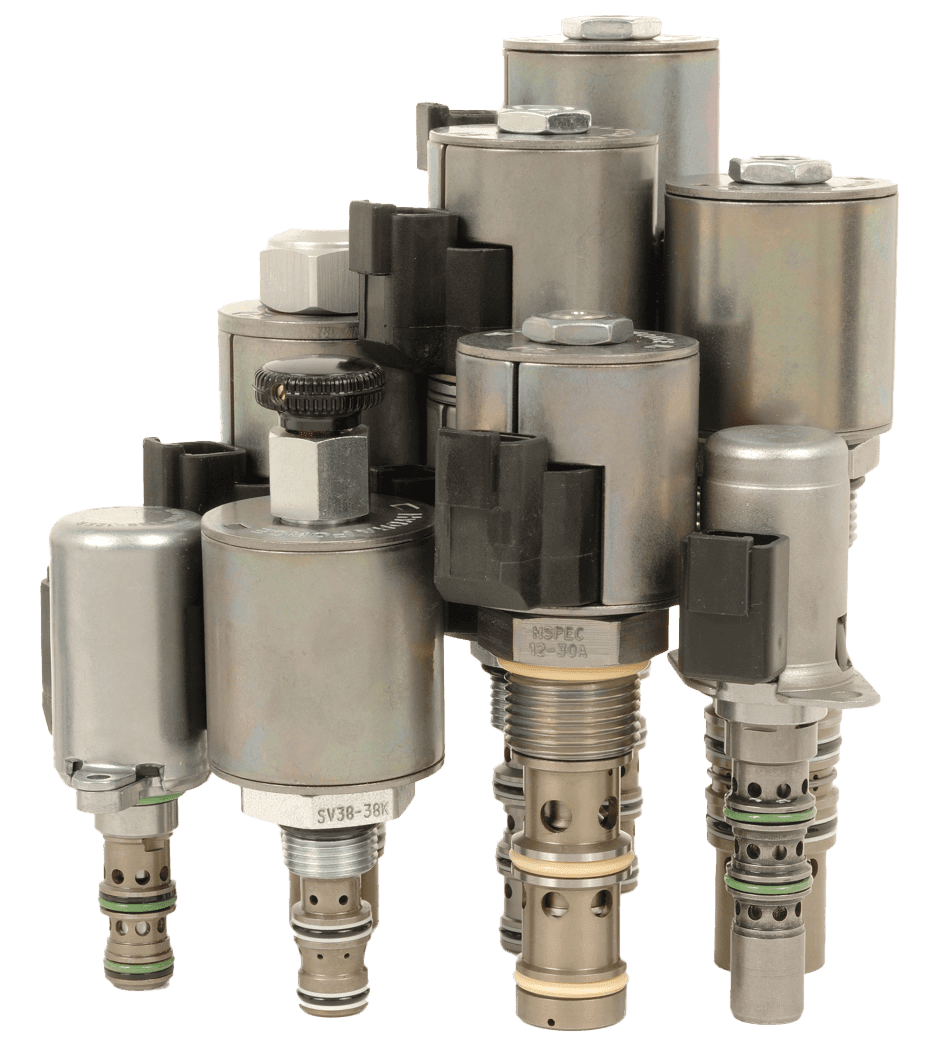

Contact usSP08-47DL Spool, 4-Way, 3-Position, “Motor Spool” (SP08-47DL)

A proportional solenoid-operated, four-way, three-position, spool-type, motor spool, screw-in hydraulic cartridge valve with lower maximum flow rate of 7.6 lpm (2 gpm).

Product Operation

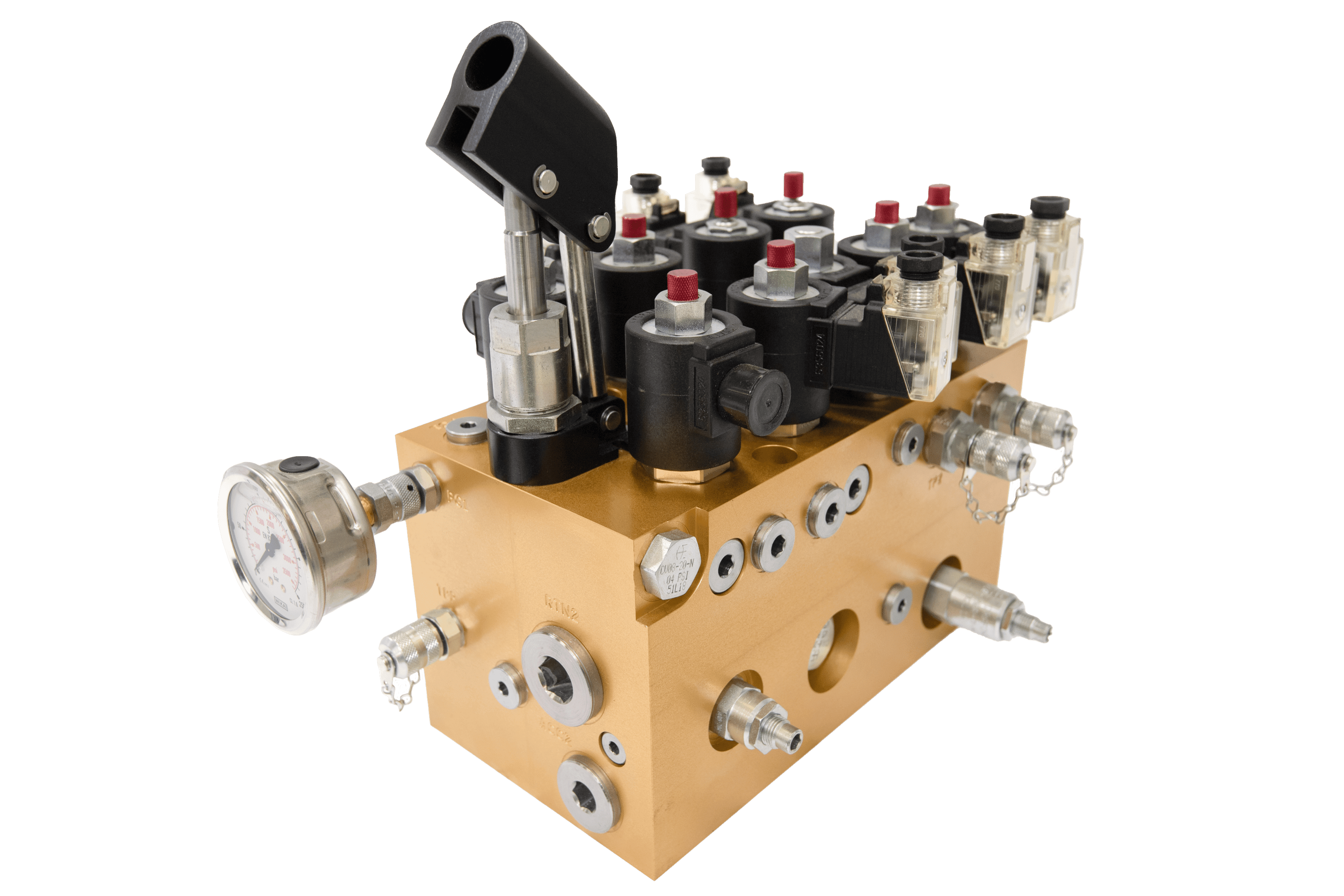

When de-energized, the SP08-47DL blocks flow to 3 while allowing flow from 2 to 1, and from 4 to 1. When coil S1 is energized flow is allowed from 3 to 4 and from 2 to 1. When coil S2 is energized flow is allowed from 3 to 2 and from 4 to 1. Initial meter-in flow begins at a nominal 0.4 amp on a 12 VDC system. Full flow of 2 gpm occurs at 1.0 to 1.1 amp on a 12 VDC system. Each coil has its own metering characteristics, which are quite similar (see performance chart). While port 1 may be fully pressurized, it is not intended for use as the valve’s inlet. In circuits where work port flows are unequal due to cylinder ratios, the higher return flow should be directed to port 2.

Product Features

• Continuous-duty rated solenoids.

• Optional manual override.

• Optional coil voltages and terminations.

• Industry-common cavity.

• Efficient wet-armature construction.

• Hardened precision spool and cage for long life.

• Cartridges are voltage interchangeable.

• Optional waterproof E-Coils rated up to IP69K.

• Designed for good linearity and hysteresis.

Product Ratings

Operating Pressure: 240 bar (3500 psi)

Flow: 7.6 lpm (2 gpm) max. (see performance chart); Flow rate is based on 50% duty cycle and coil temperature of 20°C (140°F). Consult factory if higher duty cycle and coil temperatures are anticipated.

Internal Leakage: 328 cc/minute (20 cu. in./minute) max. per side at 207 bar (3000 psi)

Hysteresis: Less than 7%

Temperature: -40 to 120°C with standard Buna seals

Coil Duty Rating: Standard Coils and E-Coils: Continuous up to 115% of nominal voltage

Filtration: See page 9.010.1

Fluids: Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 sus); See Temperature and Oil Viscosity, page 9.060.1

Installation Recommendation: When possible, the valve should be mounted below the reservoir oil level. This will maintain oil in the armature preventing trapped air instability. If this is not feasible, mount the valve horizontally for best results. See page 9.020.1

Cavity: VC08-4; See page 9.108.1;

Cavity Tool: CT08-4XX; See page 8.600.1

Seal Kit: SK08-4X-MMM; See page 8.650.1

Coil Nut: Part No. 7004400;

Manual Override Coil Nut: Part No. 4528180;

Coil Spacer: Std

D-Coil Spacer

Part No. 7012940; E-Coil Spacer Part No. 4534720; If cartridge is ordered “Less Coil,” D-Coil spacer will be provided unless an E is specified in the Coil Termination To Order section.